RAW MATERIAL - Skysun is having strong research team for selecting high quality of raw materials from india & di?erent part of world for producing high quality of tiles. Our quality assurance department checks and con?rm all incoming raw materials be?re unloading from consignment. once quality department approved then only materials is unloaded de?ned bins.

MIXING & WEIGHTING MACHINE – skysun have facility of two di?erent batching unit with self calibrated load cells for proper weighting of raw materials as per formulation given by R & D department. these self calibrated machines play very vital role in controlling quality of ?nal output.

MILLING - milling department having facility of 4 rotary mills which has capacity of 400MT per day with high content of imported alumina pebblesfor proper grinding and homogeneous mixing of each loaded materials in mills.

AGING - To achieve proper goniometry of raw powder, skysun having facility of 4000

ltrs capacity of underground tanks for proper mixing of grinned slip, is also helps in process to remove unwanted gases from slip.

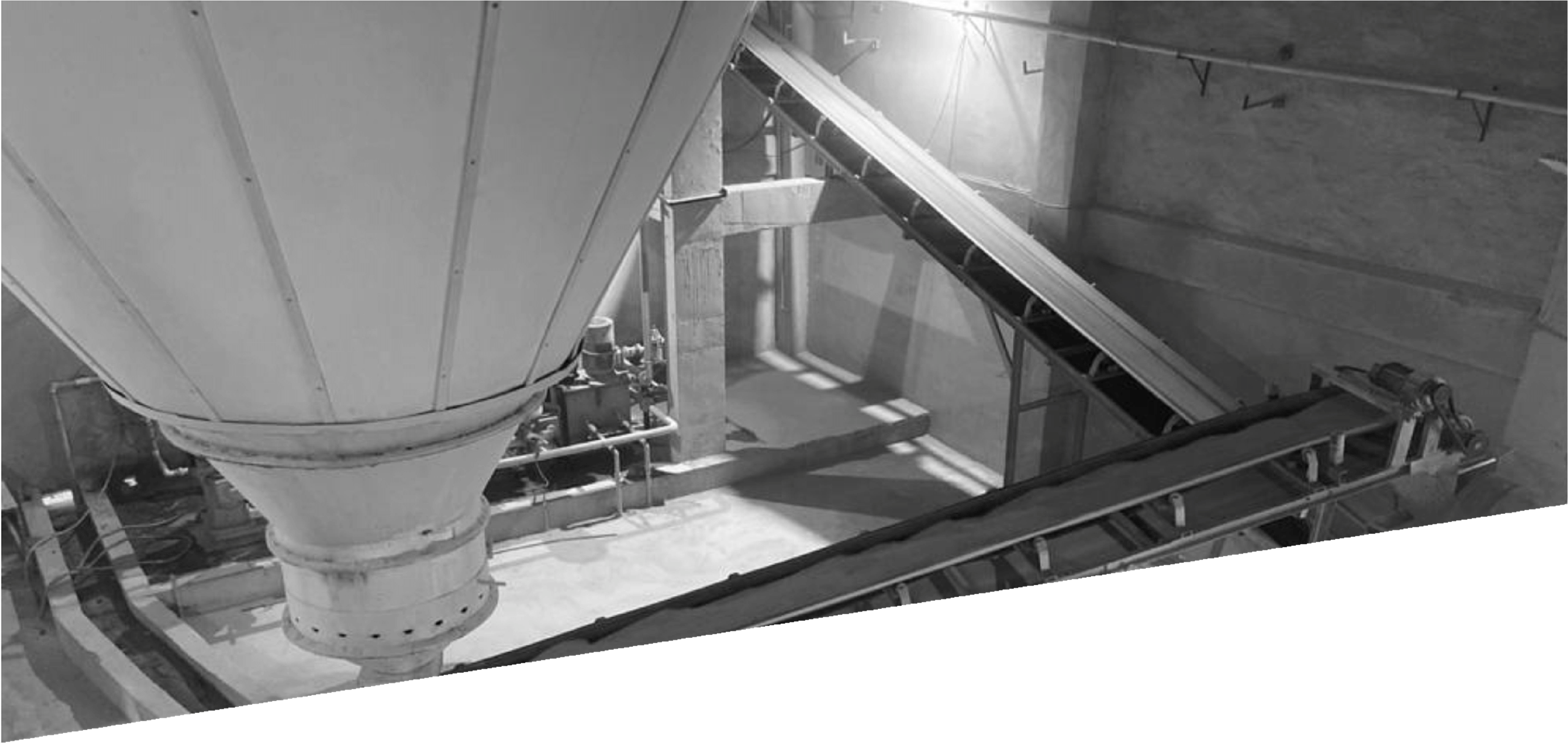

SPAY DRYER - this is very crucial stage where we can control granolometry of powder for propernpressing. skysun having spray dryer which is 100% auto controlled and allow us to achieve desire granolometry and moisture.

POWDER STORAGE - we design out powder storage in such a way that we can keep powder of many formulation & di?erent colours.powder storage system is completely controlled by programming and there is no manual acceptance is allow for changing powder for pressing.this system is customized for skysun only.

PRESS - the SACMI is natural isostatic pressing system so the tiles is free to expand there by releasing any internam tension.when it comes out of the kiln,the shape of the tiles is 100% regular without any guage error. with this SACMI we can produced tiles upto 600mm to 1200 mm with standard atomized powders and also with ?akes.we can creat di?erent structures on a tiles surface.

DRYING - ?ve layer fast drying system dryer,which remove moisuture from pressed tile for proper application of high density glazed on surface.

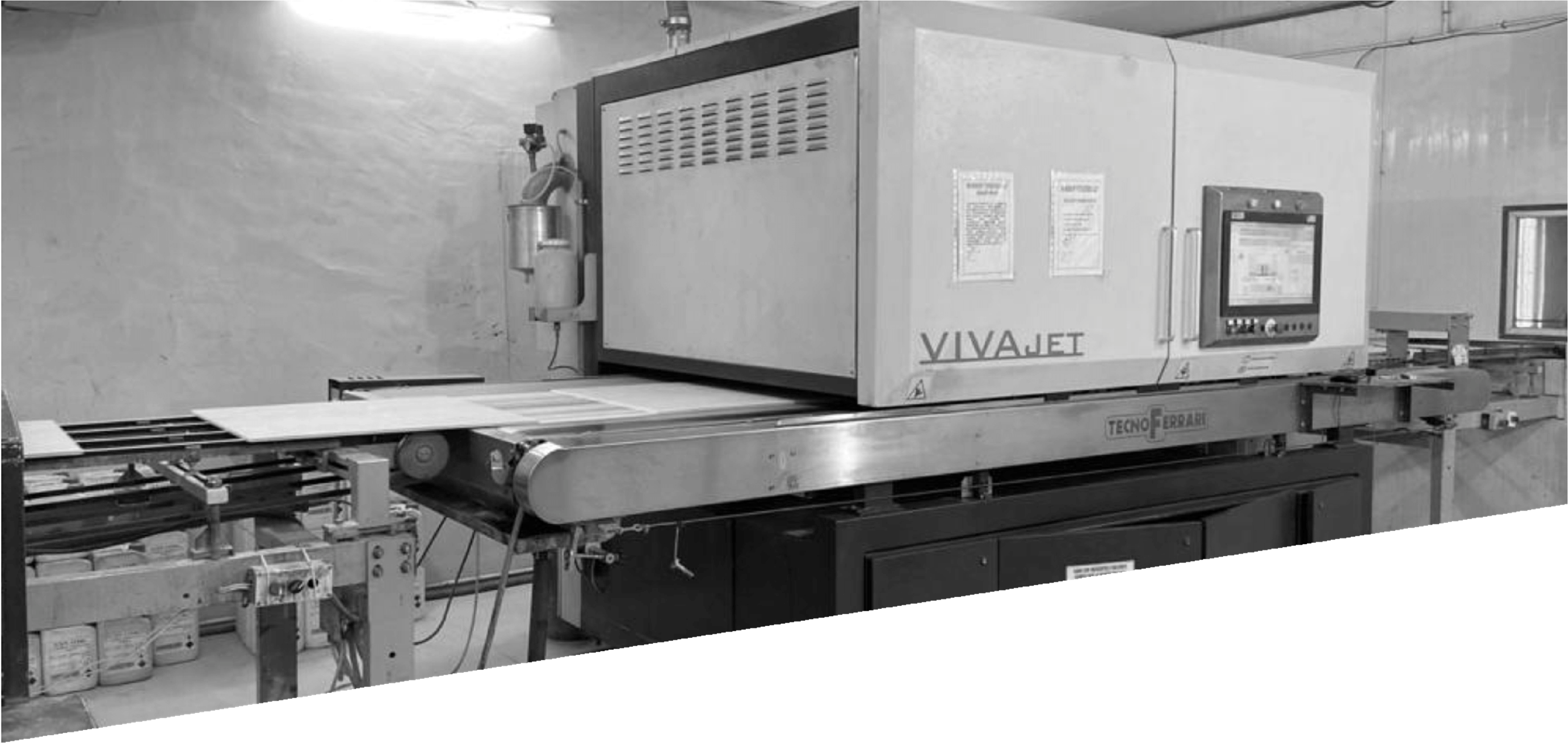

DIGITAL PRINTING MACHINE - the state art of machinery with latest generation of technology of printing head.this machine can have capacity to print HD design with natural aesthetical colors and hence its match the natural stones and desired design with colours.our machine have capacity to print any dark color on any kind of surface. hence it will enhance its beauty. we are working with 2 Digital Printing Machines With Heigher Technology.

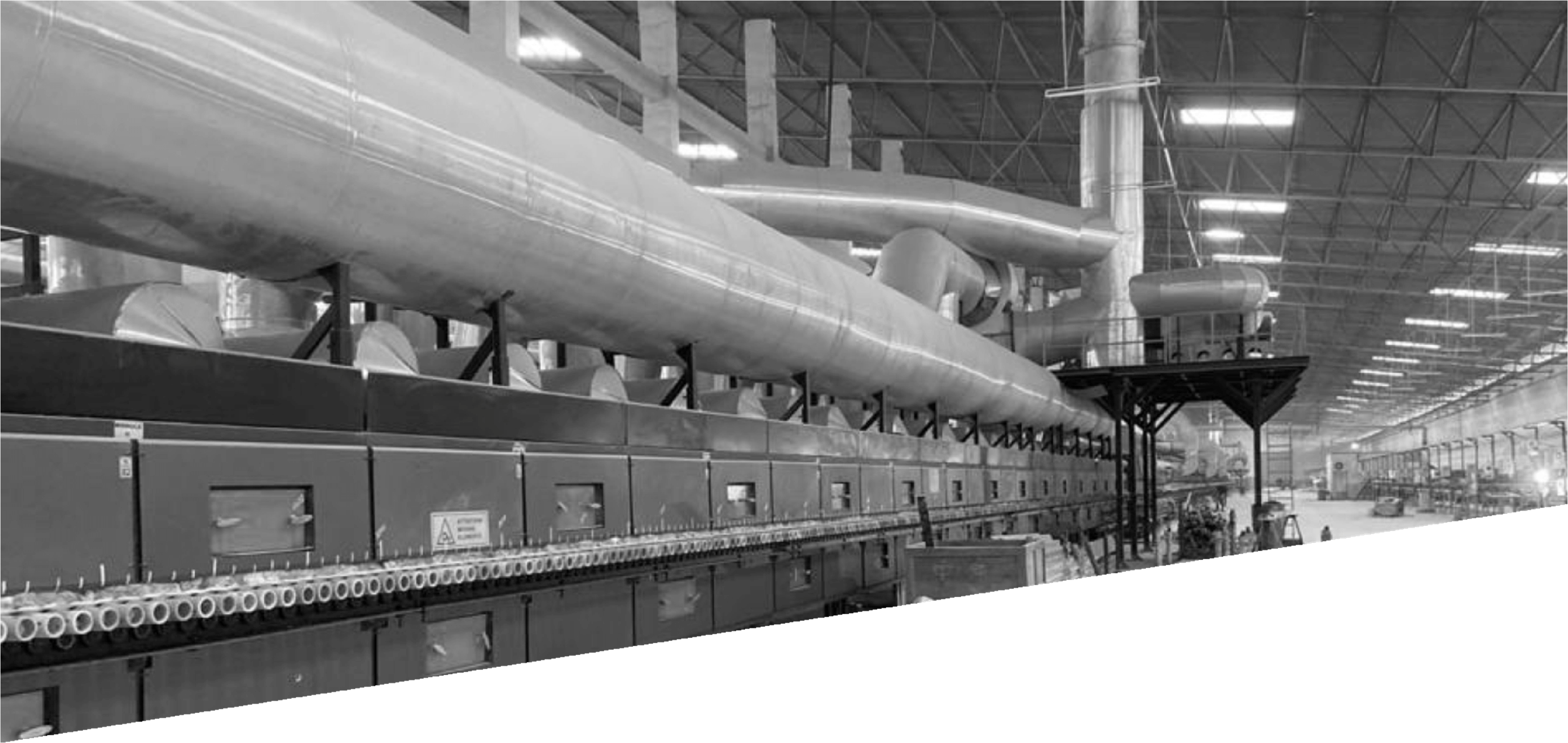

FIRING- on long time experience and in deep technical study about problems on surfaces like, surface waviness & roller impressions on surface of tiles. this problem is seen and are unavoidable in the ceramic industries all over the world.it apparently gets better after controlling in kiln and polishing. even tuning kiln and hard working on these two problem tiles cannot match original marbles surface because of its waviness and roller impressions. ?naly skysun found its way to remove these problem after discussing with manufacturer of roller kiln & many technical experts and henceforth skysun having high tech. modi?cation in combustion & ?ring system to compeltly eliminate surface.

POLISHING - we have 64 heads polishing line instead of normal polishing line,this is to improve more ?atness and high glossiness and it creates surface which is more close to natural stoes and other e?ect.

SORTING - “COMMITMENT TO QUALITY” sorting department have two facility, in the ?rst stage we have manual inspection on surface fault & physical fault on tiles and second check point have recon?rmation of their sorting in another light e?ect. this enhance more consistency and assure of quality in packed tiles.

CRAZING MACHINE - Check The Crazing e?ciency for di?erent agening.